Our approach

The engine of our success

More than 50 years of ambition and experience with high-quality plastics, coupled with a strong relationship with our customers - that’s the driving force behind our success. We closely monitor all international developments, including those in your sector. This allows us to respond rapidly to any demand for innovative products. We want to offer our customers innovative, niche-oriented and competitive products that meet the highest technical expectations. We attach great importance not only to people and the environment, but also to creating a pleasant working environment for the dedicated individuals who share our passion for innovation.

How we work

Step 1

Analysis & Design

Analysis & Design

- We start with a thorough analysis of customer requirements: rheological and mechanical properties, colour, chemical resistance, application environment and budget expectations.

- If moulding is required, we discuss mould design and specifications (material, tolerances, cavities) in close consultation with our partner(s) in complete transparency.

- Based on this, our R&D team designs a compound formula that meets both the technical requirements and cost objectives.

- For complex moulded parts, we usually start with a prototype mould to validate the design, compound and functionality.

Step 2

Prototyping & Validation

Prototyping & Validation

- We produce test batches on our laboratory mixer and carry out internal and external validations. Samples of the compound can be supplied on request.

- For moulding work, we supply test pieces and check compatibility with the mould drawing (3D measurements).

- During this phase, we provide an indicative price estimate, including any mould costs.

Step 3

Offer & Production

Offer & Production

- After approval, we will draw up a detailed quotation including:

- Price per kg of compound or per piece/metre for moulding based on MOQ* and/or graduated prices

- Mould costs (production/series mould)

- Delivery time, Incoterms, transport costs

- Proposed optimisations

- We coordinate critical quality parameters with the customer and provide a customised test report.

- We then commence production on an industrial scale, with the speed of upscaling and/or homologation taking place in close consultation with the customer, tailored to their requirements and wishes.

* Minimum Order Quantity

Step 4

Delivery & Partnership

Delivery & Partnership

- We take care of logistical coordination and timely delivery in accordance with the agreed price and conditions.

- A clear Certificate of Analysis (CoA) is included with every delivery.

- We are constantly looking for improvements in recipes and processes in order to remain cost-efficient and competitive.

- Through close collaboration, we continue to innovate and develop compounds that meet the needs of new markets and sustainability requirements.

Colour specialist

At Bekina Compounds, we specialise in developing and producing rubber compounds in virtually any desired colour. Our experienced R&D team can match colours exactly to RAL references, so that the end product always perfectly matches your specifications. Did you know that we can also help you find bio-based alternatives for your compounds? Sustainability is deeply rooted in our company, and we want to help you move forward with this sustainable approach.

Advantage 1

Perfect colour mix

Perfect colour mix

We develop the perfect colour mix for you, tailored to your wishes. We first set the colour and then we create sample plates to check for approval. This is how we achieve the perfect end result.

Advantage 2

Stable and bright colours

Stable and bright colours

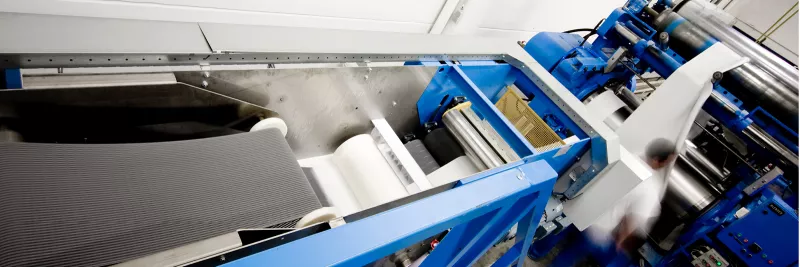

Thanks to our soot-free production, we guarantee stable and bright colours delivery after delivery. We work according to RAL code or specified reference sample, so that the end product always perfectly matches your specifications.